Stud Type Cam Follower Roller Track Roller Bearing CF18uu CF18 Kr40 Kp40-PP Kr40PP

Basic Info

| Separated | Unseparated |

| Transport Package | Carton |

| Specification | customized |

| Trademark | oem |

| Origin | China |

| HS Code | 8409100000 |

| Production Capacity | 1000000 PCS/Month |

Product Description

Welcome to SHAOXING SHANGYU FLIGHT SEIKO MACHINERY CO.,LTD !

We offer a wide variety of precision machining capabilities including high quality precision machined parts,

Mechanical assemblies,and cutom fabrication for automobile,textile machinery,construction machinery etc.

Our manufacturing and process capabilities are ISO9000 Certified.

Stud type track rollers is composed of a stud used as the tray of a group of rollers and a thick wall outer ring. The shoulder of the stud and the surface retaining ring on the stud form the guiding faces on the two sides of the outer ring. When the curve rollers are running on the plain tray or cam wheel, the inner stress on the rollers will increase due to the deformation of the outer ring. Therefore the rated load should be selected as curve roller column in this operational case.

Characteristic of Stud type track rollers

Axle diameter | External dimensions | Nut screws tight the distance of force | Basic fixed load | ||||||||||

mm | D | d | C | B | B1 | B2 | G | G1 | g1 | G2 | Cr | Cor | |

mm | Kgf.m | Kgf | |||||||||||

4 | 12 | 4 | 8 | 20 | 11 | -- | M4X0.7 | 6 | -- | -- | 0.08 | 210 | 220 |

5 | 13 | 5 | 9 | 23 | 13 | -- | M5X0.8 | 7.5 | -- | -- | 0.23 | 260 | 280 |

6 | 16 | 6 | 11 | 28 | 16 | -- | M6X1 | 8 | -- | -- | 0.3 | 370 | 400 |

8 | 19 | 8 | 11 | 32 | 20 | -- | M8X1.25 | 10 | -- | -- | 0.8 | 430 | 630 |

10 | 22 | 10 | 12 | 36 | 23 | -- | M10X1.25 | 12 | -- | -- | 1.2 | 550 | 670 |

12 | 30 | 12 | 14 | 40 | 25 | 60 | M12X1.5 | 13 | 6 | 3 | 2.2 | 810 | 900 |

16 | 35 | 16 | 18 | 52 | 32.5 | 8 | M16X1.5 | 17 | 6 | 3 | 5.8 | 1230 | 1560 |

18 | 40 | 18 | 20 | 58 | 36.5 | 8 | M18X1.5 | 19 | 6 | 3 | 8.5 | 1500 | 2500 |

20 | 52 | 20 | 29 | 66 | 40.5 | 9 | M20X1.5 | 21 | 8 | 4 | 12 | 2110 | 3140 |

30 | 90 | 30 | 35 | 100 | 63 | 15 | M30X1.5 | 32 | 8 | 4 | 46 | 4630 | 6300 |

Custom size requirement are also available

Manufacturing strength & Vehicle processing line

1.Professional operators

2.Adopting advanced CNC machine tools in Japan

3.Totally enclosed production workshop

4.Experienced managers

5.Digital control production line

6.Advanced level of technology

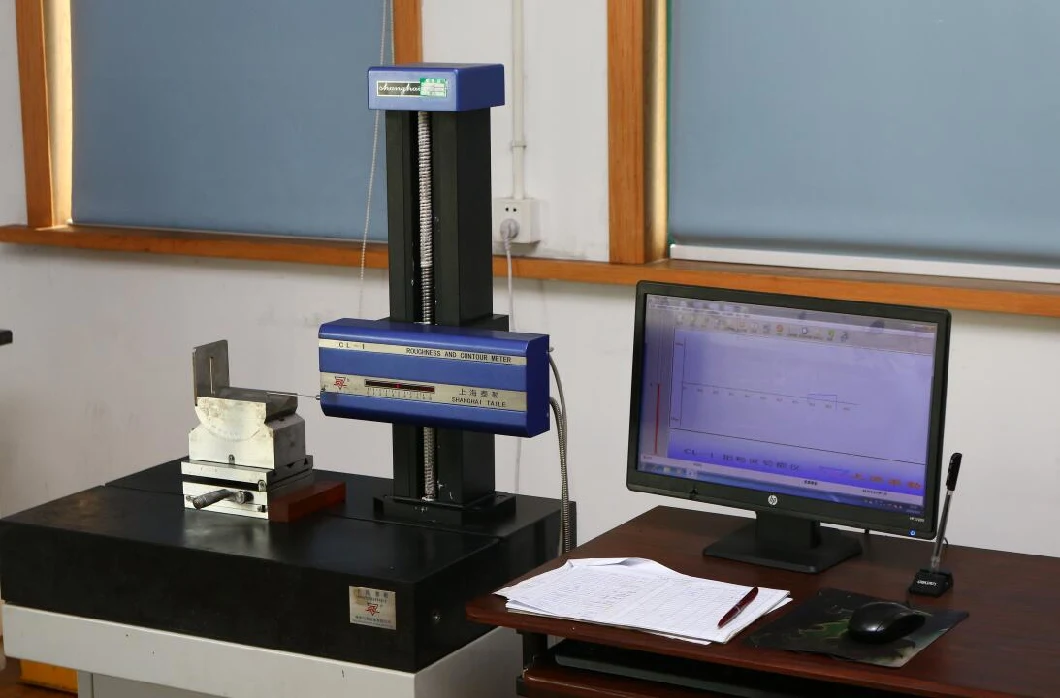

Production Detection

1.Complete testing facilities

2.Perfect measurement methods

3.Perfect production detection methods

4.Strong QC team,conduct comprehensive quality control