Category

Ireland Mccolskey J45 Jaw Plates Jaw Die Corrugated Crusher Parts

Product Names: Jaw Plate,Jaw Tooth, Jaw Die, Jaw Teeth, Stationary jaw , Steady Plate, Fix plate, Fixed Jaw , Swing Jaw

Basic Info

| Model NO. | Mccolskey J45 Jaw |

| After-sales Service | Guarantee to Fit |

| Warranty | Premium Wear Life |

| Certification | CE, ISO 9001:2000, ISO 9001:2008 |

| Standard | GB, ASTM |

| Surface Treatment | Spray-Paint |

| Manufacturing Process | Casting |

| Color | Customized |

| Drawing | Original or Customized |

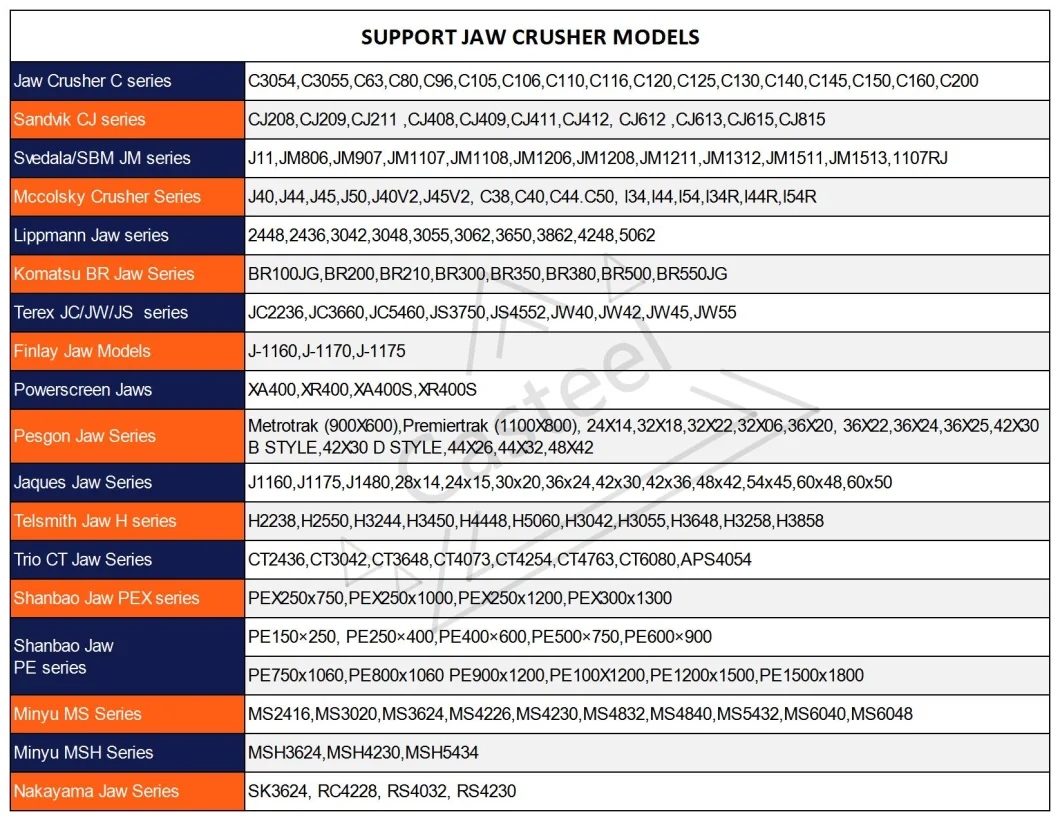

| Crusher Brands | Telsmith Lippmann Pioneer Mccolsky Osborn |

| Delivery Time | 15-30 Days |

| Condition | New |

| Type | Jaw Plate |

| Use | Ore Mining |

| Machine Type | Jaw Crusher |

| Experience | More Than 10 Years |

| Crusher Models | J40, J44, J45, J50, J40V2, J45V2 |

| Transport Package | Steel Pallet |

| Specification | MN13CR2, MN18CR2 |

| Trademark | CASTEEL |

| Origin | China |

| HS Code | 8474900000 |

| Production Capacity | 5000 Ton/Year |

Product Description

Product Names:

Jaw Plate,Jaw Tooth, Jaw Die, Jaw Teeth, Stationary jaw , Steady Plate, Fix plate, Fixed Jaw , Swing Jaw Plate, Movable Jaw

Cheek Plate /Side Plate,side Liner,up Liner and lower Liner

Jaw Wedges /Taper Wedges, Jaw Lock

Toogle plate, toogle bearing, toogle seat.

Bowl Liner /Concave Ring, Cone Liner

Mantle Liner, Cone Liner

Blow Bar/ Hammer

Impactor Liner,Apron Liner, Impact Plate, Side Liner

Mill Liner ,SAG mill Liner

Material Capacity & Following Standards

| US | Australia | British | German | South Africa | Japan | China |

| ASTM A128/A532 | AS2074 H1A/-H1B | BS3100/ BS4844 | GX 130 MnCr2 | SABS 407 Type 1 & 2 | SCMnH11 | GB/T 5680-2010 |

We Supported a wide range of alloys with different Heat treatment capabilities Austentic Manganese steels 14%MN, MN13CR2, MN18CR2, MN22CR2 MN13CRMO, MN18CRMO, MN22CRMOHigh chromium white cast irons Chrome 15%, Chrome 25%, Chrome 30% Cr25NiMo, Cr30NiMo and EtcAlloy steels Various grades (SWB Germany)High and low Carbon SteelNi-hard 2,3, 4

Customized Steel

| Material | C | Mn | Si | Cr | Molly | Nikker | P | S | Suit to |

| Mn14Cr2 | 1.0-1.3 | Mn:11-14 | 0.3-0.6 | 1.7-2.4 | --- | --- | ≤0.05 | ≤0.03 | Jaw Plate, Side Plate,Mill Liner |

| Mn14Mo1 | 1.0-1.3 | Mn:11-14 | 0.3-0.6 | --- | 0.8-1.2 | ---- | ≤0.05 | ≤0.03 | Shredder Hammer, Track Shoe |

| Mn18Cr2 | 1.1-1.4 | Mn:17-20 | 0.3-0.6 | 1.7-2.4 | --- | ---- | ≤0.05 | ≤0.03 | Jaw Plate, Bowl Liner, Mantle |

| Mn18Cr2Mo0.6 | 1.1-1.4 | Mn:17-20 | 0.3-0.6 | 1.7-2.4 | 0.6-0.8 | --- | ≤0.05 | ≤0.03 | Hard Abrassive Rock Crushing |

| Mn22Cr2Mo | 1.1-1.4 | Mn:20-24 | 0.3-0.6 | 1.7-2.4 | ---- | ---- | ≤0.05 | ≤0.03 | Heavy Duty Concave,Mantle |

| KMTBCR15 | 2.8-3.2 | Mn:0.6-0.8 | 0.6-0.8 | 14.5-15.5 | 0.2-0.3 | 0.2-0.3 | ≤0.06 | ≤0.06 | Paddle Arm ,Tip And Mixer Liner |

| KMTBCR27 | 2.8-3.3 | Mn:0.6-0.8 | 0.6-0.8 | 26.5-28 | 0.3-0.5 | 0.3-0.5 | ≤0.06 | ≤0.06 | Blow Bar, Paddle tip ,VSI Parts,Anvil |

| KMTBCR30 | 2.8-3.3 | Mn:0.6-0.8 | 0.6-0.8 | 28.5-30 | 0.3-0.5 | 0.3-0.5 | ≤0.06 | ≤0.06 | Blow Bar, Paddle Tip, VSI Parts |

| Cr27Ni2Mo1 | 2.8-3.3 | Mn:0.6-0.8 | 0.6-0.8 | 26.5-28 | 0.8-1.2 | 1.5-2.0 | ≤0.06 | ≤0.06 | Heavy Duty Blow Bars |

| Ni-Hard | 2.8-3.2 | 0.2-0.8 | 1.5-2.2 | 8.0-10.0 | 0.3-0.5 | 4.0-5.5 | ≤0.06 | ≤0.06 | Mill Liner, Augers, Paddle Tip |

| Martensite Alloy Steel | 0.3-0.6 | 0.8-1.5 | ≤1.2 | 1.8-2.3 | 0.2-1 | 0.5-0.8 | ≤0.06 | ≤0.06 | Blow Bar, Mill Liner and etc |

| Carbon Steel | 0.08-0.25 | 0.3-0.6 | 0.15-0.35 | ----- | ---- | ---- | ≤0.045 | ≤0.045 | Torch Ring,Shell , Bowl ,Cone |

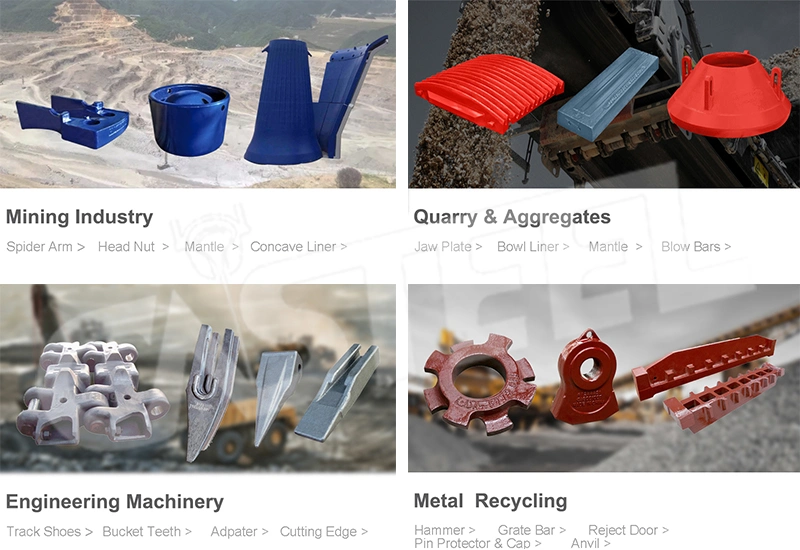

Applications:

Widely used in Mining Industry, Quarrying & Aggregate, metallurgical and Recycling industry, construction Plants, heavy engineering Industries , chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone, quartz,Basalt,Granite, Building Waste ,Metal Scrap and so on.

Design and Development Capabilities:

With professional designers and efficient mould making, we can correctly and quickly implement new product development.Our company trained a group of professional designers, who have gotten long term training in Our company; besides professional skills,we think highly of complementary relationships on the job,and built teamwork,enabled personal experience and collective wisdom to be brought into play or productively. As a result,we can cooperate with customers,swiftly understand and work with them,also gain the trust of painters.

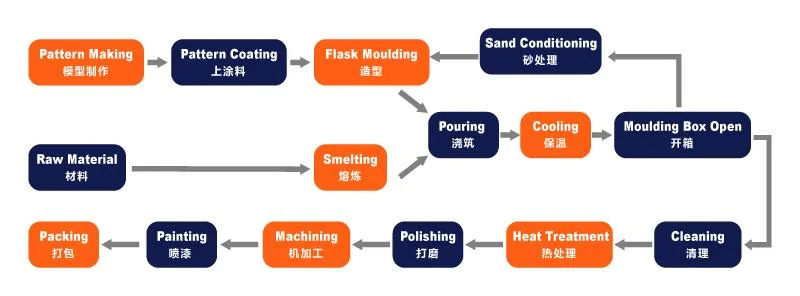

Manufacturing Process:

Provide measurement check, Metallographic, machinery performance, hardness, ultrasonic inspection, coloring flaw testing, ultrasonic flaw testing and result a report before shipping

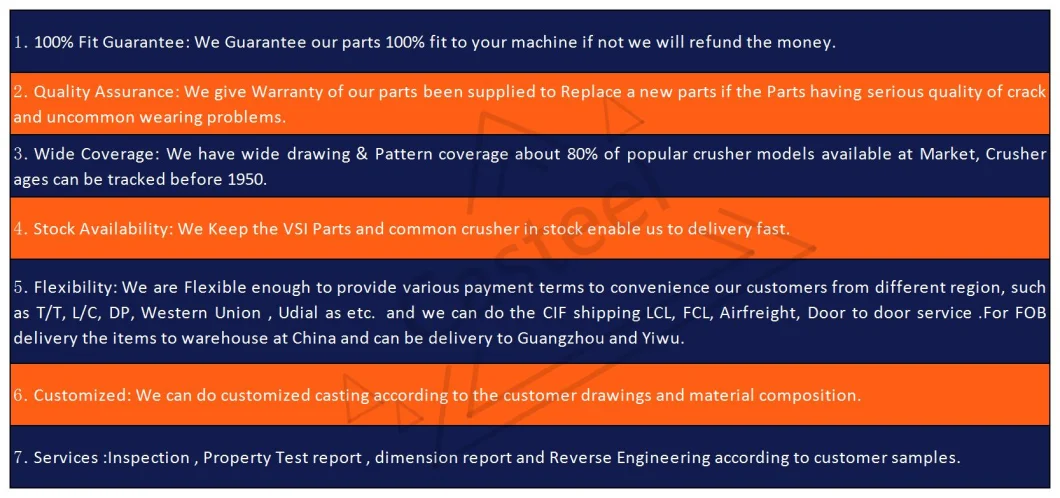

Advantages and Guarantee:

Test:Chemical Analysis

Dimension Measurement

Heat-Treatment Record

Mechanical Property Test

Hardness Test

UT/PT Test

Our Factory: